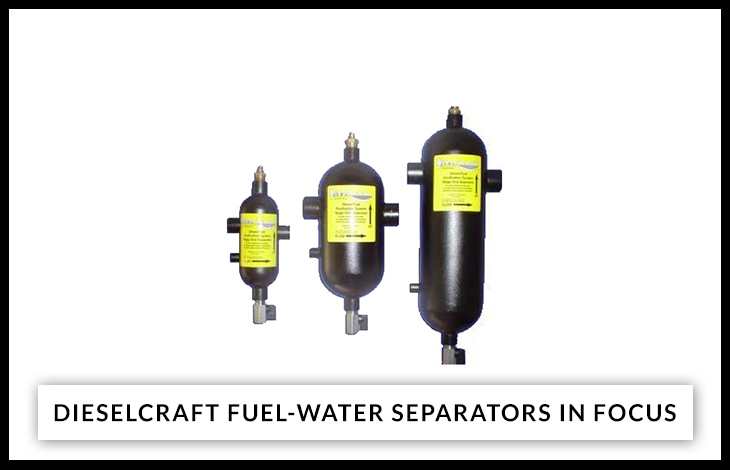

Dieselcraft Fuel-Water Separators in Focus

The presence of water in diesel is not strange, in fact, there is almost always some water mixed in with your diesel. This water doesn’t pose a problem as long as it remains dissolved below the saturation point of your fuel. The challenge comes when the amount of water in the diesel goes above its saturation level and begins to fall out of the fuel as free water.

The saturation point of a fuel is not constant. It varies according to the temperature as well as the ratio between the petrodiesel and biodiesel. The range of saturation points in diesel can be as low as 50 ppm or as high as 1800 ppm.

If you want to keep your engine safe from water damage, you need to know the saturation points of the diesel you use in high and low temperatures. The difference between the saturation points in a single sample of diesel when it is warm and cold can vary by up to 30 ppm. For this kind of sample, you need to reduce the water for the diesel while it is cold. If you purify it when it is hot, you risk the accumulation of water in your tank when the fuel cools down.

Many diesel engine manufacturers advise you to invest in a system that prevents any free water from reaching the engine. Prolonged exposure to free water can lead to permanent damage to the engine. Dieselcraft have developed a fuel water separator-purifier that promises to eliminate 99% of the free water in your oil. The water separation process also eliminates up to 95% of other impurities that are common to diesel fuel. This purifier is available in six models that are suitable for a range of diesel engines from 200 hp to 2,000 hp.

Hazards Of Water In The Engine

There are several reasons why it is not a good idea to let visible water to move freely in your fuel system or to get into your engine. Here are a few of the most important ones.

Bacteria Growth

The presence of free water encourages the growth of bacteria and other microbes. This is especially true if the diesel you use is blended with biodiesel which is naturally hygroscopic and thus attracts more water than petrodiesel. There is one infamous microbe know and the ‘diesel bug’ that is notorious for contaminating diesel fuel because it thrives in environments that combine free water and diesel. These microbes create resins and build up sediments in your tanks and clog components of your engine such as the fuel injectors effectively reducing the efficiency of your engine.

Corrosion

Free water has the tendency to form rust and corrode the walls of your fuel tank. The corroded fragments then flow with the fuel and can cause abrasion and serious damage to the more delicate components of the fuel system such as seals and valves.

Fuel Efficiency

When there is too much water in the diesel, it affects the fuel’s Cetane rating and reduces the efficiency of the fuel effectively interfering with the overall performance of the engine and its components.

How The Dieselcraft Fuel-Water Separator Works

Unlike the conventional fuel filters, the diesel-craft fuel-water separators don’t use filters and have no moving parts. A typical dieselcraft fuel-water separator consists of a self-priming centrifugal pump and a 99% efficient separator/ purifier along with a series of connecting hoses and valves.

The dieselcraft fuel-water separator works on the surface tension and fluid density principle. The clear difference in the surface tension of water and diesel can be exploited to separate the two fluids completely. This fuel-water separator works by spreading the fluid mixture over a large area and allowing the denser fluid to form droplets and fall out of the mixture due to its own density.

These purifiers are designed to maximize the flow duration of the fluid mixture to over the separation area. The time it takes for fluid in equilibrium to flow through the system is referred to as the residence time. In order to increase the efficiency of its purifiers, dieselcraft systems match the flow rate of the fluid mixture to the surface area and activated alumina.

When this method is combined with long residence time, it becomes easier for the water to agglomerate and drops out of the fuel. Otherwise, you will only succeed in separating bad fuel from worse fuel.

Conclusion

While it is difficult to prevent water from ever getting into your fuel, it is possible to control its effects. Installing the right equipment to deal with water contamination in your engine can save you a lot of money in repairs and downtime. Efficient systems like the dieselcraft fuel-water separator are designed to save you the trouble of worrying about water getting to and damaging your engine.

Read More: